As a new era of lighting industry is driven by the revolutionary LED technology, many IC experts aim to offer the best solution for various LED application. In particular, LED illumination efficiency and life span has always been a core concern, therefore, Macroblock identifies the problems of traditional constant voltage LED drivers and develops 1.2A constant current DC-DC buck converter-MBI6650 with hysteretic PFM control technique, which enhances power efficiency up to 93% and well extends the life time of LED. With built-in protection function, the MBI6650 shows an excellent system reliability and security. Recently it also successfully assists customers to LED street lamp design, which makes Macroblock more stand out in market. In order to provide well-though-out service to customers this year, Macroblock is ready to conduct seminars in September in China and present the MBI6650 converter at Electronica 2008 Munich, Germany from November 11th to 14th (Booth #A5.532).

Hysteretic PFM Traditional LED Driver – Constant Voltage TypeFor LED applications, the brightness of LED is varied with the level of forward current which means the larger forward current results in the brighter LED. Forward current can be controlled by either constant voltage source or constant current source.

According to Figure1, the design presents the constant voltage source controls LED current with an added current limiting resistor. For example, if the input voltage is 5V, the forward voltage of LED is 3.6V, the desired LED current is 20mA, and then the calculated R1 is 70Ω. However, the LED current is directly proportional to the degree of the variation of input voltage or of the LED forward voltage, which results in the noticeable differences in LED brightness. Furthermore, the power dissipated in the current limiting resistor causes the heat and efficiency problems.

Traditional LED Driver-Constant Current TypeAnother method of regulating LED current is to operate the LED with constant current source. In Figure 2, a liner regulator supplies constant current to LEDs, and the output current can be programmed by R1. Compared an LED driver with constant voltage mode, the constant-current LED driver is able to control the LED current despite any influences of variations of the input voltage and LED forward voltage. However, the increasing voltage difference between the input voltage and the total LED forward voltage still brings the heat and efficiency issues.

Hysteretic PFM Control Scheme

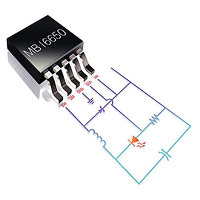

Hysteretic PFM Control Scheme Macroblock reveals its new discovery on LED technology-Hysteretic Pulse Frequency Modulation (PFM) control scheme, which especially brings high efficiency improvement at the light loading condition. Macroblock successfully applies such technology on newly released DC/DC converter-MBI6650. Figure 3 illustrates the application circuit of the MBI6650 and Figure 4 demonstrates the waveform of the hysteretic PFM control scheme. In Figure 3, VSEN is the voltage across RSEN , which can determine the output current. VH is the high level reference voltage, which value is 1.3 times of VSEN, and VL is the low level reference voltage, which value is 0.7 time of VSEN. VSEN is lower than VH as power is on, the internal MOSFET of the MBI6650 will be turned on and then VSEN will increase with IL. Until VSEN is equal to VH, the MOSFET will be turned off, and VSEN will decreases with IL. When VSEN decreases and goes down to VL, the internal MOSFET will be turned on again, and repeat the previous action. The inductor current will always work in the Continuous Current Mode (CCM) in terms of advantages of the Hysteretic PFM control scheme, it is regarded as a good solution for reducing the LED ripple current.

Comparing to traditional PWM method, the power efficiency reaches 60% at light loading, the Hysteretic PFM control scheme not only strengthens system stability, but upgrades the efficiency up to 85% at light loading and 90% at heavy loading. By combining the features of adaptive output switching frequency and audio frequency skip, both higher current and frequency can be reached as well as avoiding the noise interruption when the MBI6650 is activated.

Full Protection for LED Lighting SystemWith configured only 4 extra SMD components, the MBI6650 helps to reduce the PCB layout area and brings more cost effectiveness to customers. It also can operate under an input voltage range of 9V to 30V for high power LED applications. Furthermore, MBI6650's unique thermal protection function with the temperature limit of 140˚C prevents the drivers from overheating. Besides, UVLO, open-circuit and short-circuit protection functions are well-equipped to ensure the safety of the lighting system.

Facing the huge competition in LED technology, Macroblock keeps offering the best solutions with advanced technology in LED illumination. Macroblock welcomes you to visit us at technical seminars in China this September, and at booth #A5.532 at Electronica 2008 in Munich, Germany in November. For more information regarding Macroblock, please refer to http://www.mblock.com.tw/

About Macroblock

Macroblock regrades itself as a mixed-signal design house,

specializing in the power management and providing solutions for LED applications.

Through unceasing effort over all these years,

Macroblock's LED drivers have been successfully applied worldwide on

LED outdoor video display panels, LED billboard display, freeway LED message board, road sign and street lights.

Macroblock's achievements and credibility are widely recognized worldwide,

such as, China, U.S.A, Europe, Russia, Japan and South Korea.

Macroblock receives ISO9001:2000 certification in 2004

and ranked 9th in honor on Global LED Driver Supplier Share by IMS Research in 2007.

More solutions for LED lighting, LED display, LED backlighting systems at http://www.allproducts.com/ee/macroblock Pleas also contact Macroblock for more information.